-

RPSF

- Model

RPSF

-

Description:

Automatic Filler Paper Manufacturing Machine

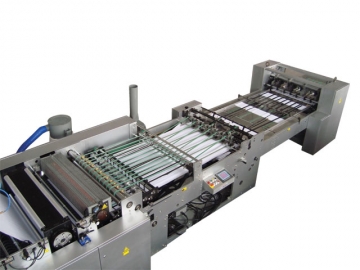

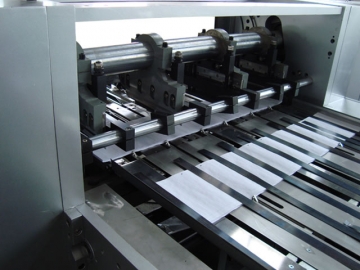

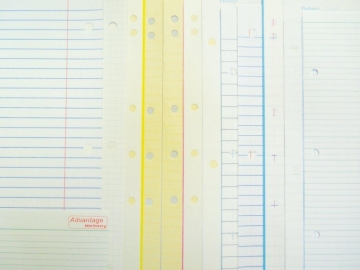

The Advantage Machinery Model RPSF is an automatic filler paper manufacturing machine that is made using state of the art technology and quality components. The paper on the RPSF is roll fed, and then printed using a flexo ruling tower. The paper is then transported through the rotary punching unit where the holes for the filler paper are punched. The paper is then cut using a rotary cutting knife and collated into groups. An optional inserting unit is available for the top sheet or separators. The group is transported into the cutting section where the filler paper is cut to final size. The delivery table groups the filler paper into the desired quantity. Online shrink packaging system is available for the complete automatic filler paper solution.

Imperial (in)

ModelRPSFMaximum Speed (m/min)250Unwind Stand1Reel Width (in)22 7/8" - 40 1/8"Max. Roll Diameter (in)51 1/8"Paper Thickness (g/m2)50 - 120Flexographic Printing Units4Colors on each side2Printing Image Length (in)8 3/8" - 26 3/8"Rotary Cross Cutter1Cutting Length (in)8 3/8" - 26 3/8"Slitting Precision (mm)0.5Max. Cutting Width (in)12 1/2"Max. Speed (units/min)40Group Delivery (sheets)20 - 500

Metric (mm)

ModelRPSFMaximum Speed (m/min)250Unwind Stand1Reel Width (mm)580 - 1020Max. Roll Diameter (mm)1300Paper Thickness (g/m2)50 - 120Flexographic Printing Units4Colors on each side2Printing Image Length (mm)210 - 670Rotary Cross Cutter1Cutting Length (mm)210 - 670Slitting Precision (mm)0.5Max. Cutting Width (mm)320Max. Speed (units/min)40Group Delivery (sheets)20 - 500

-

Garrido-Advantage Machinery- A leading manufacturer of packaging machinery

7258 NW 66st., Miami, Fl 33166, USA Ph(305) 593-9030 - Fax(305) 593-9031 Email:sales@garridousa.com